The Science

History and Inventions

Scientists and engineers are developing devices that can detect and identify smells. Until very recently, odour measurement devices have mainly been in the category of laboratory instruments. In the air pollution domain, the requirement has been for devices that are sensitive, reliable and robust. In addition, they must be validated by the human experience of odour. E-Nose Pty Ltd of Australia has made the break-through, by inventing an industrially robust e-nose that provides continuous and real-time measurements for determining chemical emissions and environmental odour, in various outdoor industrial settings. The E-Nose Pty Ltd devices can reliably identify the odour and its source, and validate it against what humans say they are smelling at the time. The device applications range from air pollution monitoring, security devices and medical diagnostics.

E-Nose Pty Ltd, founded in February 2003, is a spin-off of the Centre for ChemoSensory Research, University of New South Wales (UNSW), and the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Sydney, Australia. The founders include Dr. Graham Bell (trained in Psychology and Physiology) and six scientists and engineers who have carried out extensive research in the field of smell and electronic noses.

How the sensor array works

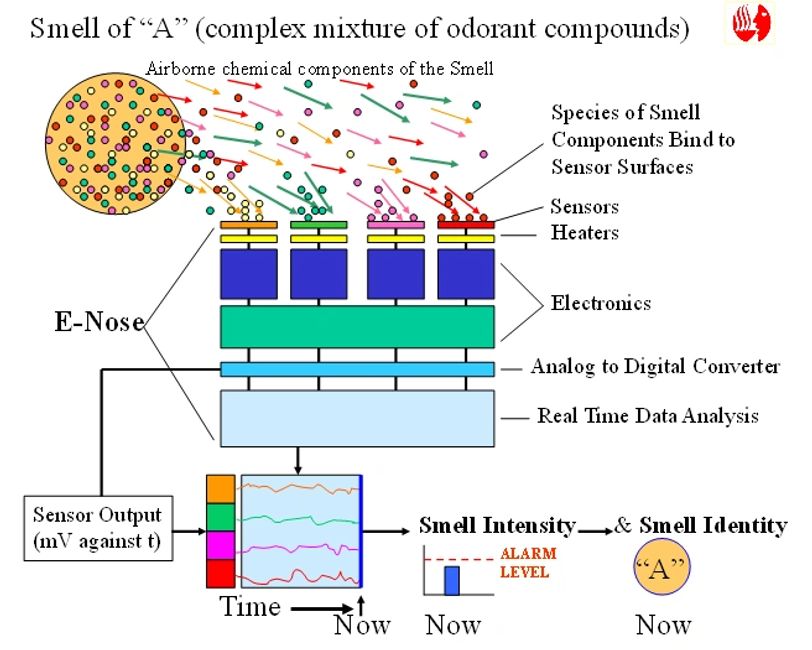

An e-nose consists of an array of chemical sensors (similar to the pixels in a camera’s diode array for detecting light) which are usually a small number (unlike in visual detector array) of metal oxides or conducting polymer electrodes that can change their physical properties (electrical resistance) when they react with certain chemicals. The surface of the electrode is “doped” with a special material (e.g. a rare earth) to which only certain species of molecules adhere (adsorb). When molecules land on the surface the change a resting electrical potential across the electrode that can be measured as a voltage. The molecules on the surface are burnt off rapidly burned off (oxidised) means of a heater located under the electrode, thereby returning the electrode to its previous resting potential. The change in electrical resistance across the sensor is converted into a digital signal. The digital signal is interpreted by a processing unit that can characterize the odour. Airborne molecules that people report as “smells” (pleasant or unpleasant, strong or weak, usually consist of complex mixtures of hundreds of species of molecular compound. E-Nose Mk4 device is a fully automated, portable device that provides continuous (24 hours, 7 days a week) real-time data from an array of six sensors, designed to run reliably in hot and cold conditions, and providing unique patterns of response (like a camera) to the hundreds of molecular species comprising the human perceived environmental odour. The following diagram illustrates how a sensor array (e-nose) produces information on the intensity and quality of complex odour mixtures:

Industrial robustness and reliability are other features that add on to the application. E-Noses deployed outdoors or where they may be vandalised, consist of a sensing unit enclosed in a protective weather hutch and iuf necessary guarded by a secure fence, a stand-alone solar power source with appropriate ancillaries, IoT electronics, transmission of data to a remote server, display and diagnostic software accessible via internet by authorised recipients. Data, held in a “cloud”, is accumulated for post-hoc analysis and reporting. The continuous performance of the devices facilitates rapid response and preventive maintenance, ensuring minimal stoppages in the information stream from individual e-noses. Hence, a network of smell surveillance can be maintained around a large industrial area. An alarm system can be incorporated to inform operational management when something unusual, or known to signal danger, has occurred.

The E-Nose devices have been proved effective in the petrochemical industry, the meat processing and waste treatment industries and in resolving disputes between communities and emitters in a number of contexts, including cattle smells, sewage, and pig farms. With the internet now widely available, it is possible to have remote real-time analysis of data and visual displays, related to the exact GPS positions reported from the devices. Medical diagnostics and process control are other application segments of E-Nose Pty Ltd.

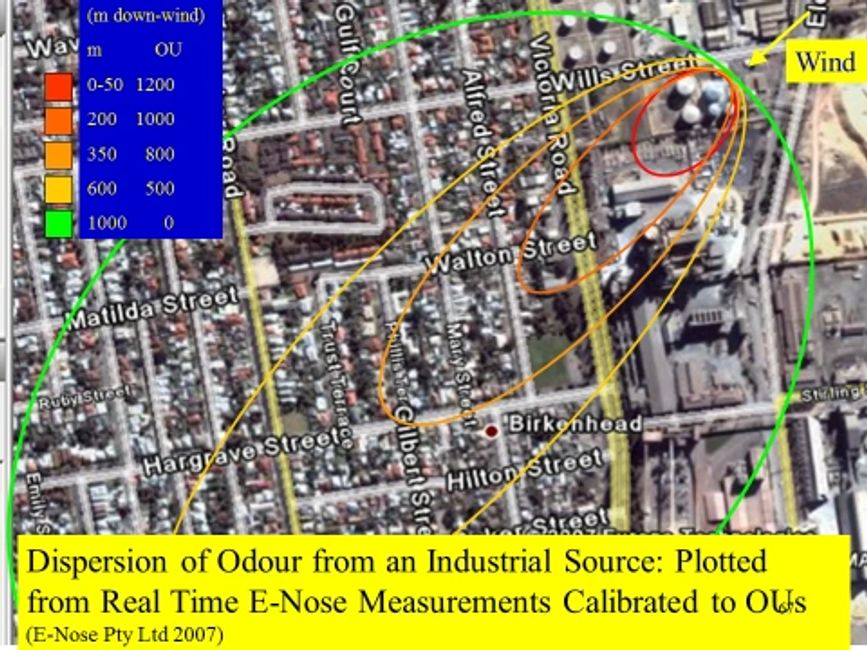

In an assignment for an international oil company, e-nose output voltages were calibrated against human “odour unit (OU)” measurements (the number of dilutions of a smell from its human threshold). It was found, that the device provided useful data down to one OU. Application specificity, reliability, robustness, small size, low-cost and real-time measurement are the distinctive features of E-Nose’ e-nose device. The software used in the device procures real-time continuous measurement. This stands in contrast to the method of taking bagged samples of air and returning to a laboratory to analyse them (dynamic olfactometry).

E-Nose Pty Ltd holds a wide range of patents with respect to e-nose technology. The patents cover sensor selection, prediction of odour events, and instant odour identification. Algorithms based on neural networks and Bayesian theory have been devised for classifying the nature of odour.

In a recent work for a petrochemical industry, E-Nose Pty Ltd was able to that in one wind direction the nuisance odour was the client's odour, but with a slight change in direction it was a neighbouring industry's odour. The device output can be expressed in units related to human smell threshold and hence it is possible to predict the odour and the distance from the source of odour.

Fingerprinting and Interpretation

E-Noses consist of a number of chemical sensors clustered in an array from which composite information represents what people call “smell”. Most smells are very complex mixtures of airborne chemicals, but a smell can also be a vapour consisting of only one volatile compound. An e-nose can therefore ‘fingerprint” both single compound vapours, such as rotten egg gas, H2S in low concentration, and those consisting of hundreds of compounds, such as the aroma of coffee. People are remarkably good at identifying subtle differences in the mixtures and attributing the name of a smell to them. E-noses can also work outside the range of human perception to detect and identify non-smelly and potentially lethal vapours, such as H2S in high concentration. However, the main interest in e-noses is in their ability, like the human’s, only objectively, to put, a name to a complex set of chemical signals. One important need for e-nose technology has arisen from growing intolerance by communities of air pollution and the promulgation of laws to reduce or eliminate nuisance odours, which now require polluters to measure and manage their emissions.

The first generation of commercial e-noses were laboratory instruments that attempted to solve every possible problem including detection of extremely low concentrations of chemicals. They tended to be humidity sensitive, required complicated sample preparation, cost a small fortune, and could not be operated by an unskilled person.

The second generation of e-noses is where E-Nose Pty Ltd came in. It has adopted a strategy of tailoring e-noses to specific customer problems which do not require extreme sensitivity and which will be robust for operations in industrial settings, and can used by ordinary semi-skilled staff. We have produced a range of e-nose devices with these features, as is described elsewhere in this application, which are working and lasting well inside factory boundaries and are gaining growing acceptance by customers and EPAs.

The sensor arrays have been “tailored” for specific tasks, such as abattoir odour, petrochemical and heavy industry, inks and paint, and human and animal research (see figure below. We have also been working long and hard on the question of odour identification, to meet the need of our customers to be alerted as soon as an odour event occurs and to do so when their odours are emitted and not someone else’s.

To do this off-line is not difficult, but where time is of the essence, it is difficult. We have, over the last two years, devised, tested, and programmed a patented algorithm that identifies odours from memory, but also does so as fast as the device can gather in data, currently at one per second. This offers solutions to existing customer needs and presents the opportunity to expand our markets, expand our technical offerings with new devices, such as moving vehicles that can track down a source of odour, and steal a march on competitors on a global scale. We now have e-nose devices that can be deployed remotely on or around an industrial polluting site, can make instantaneous decisions on what it is smelling, and can relay the data back to a remote operator and data repository. By virtue of this technical advance, our company has become a stand-out on the world stage.

No competitor in the world has our patented algorithm for instantaneous odour discrimination. We are now providing clients with a distinct technical advantage.

How odours move: weather conditions that trigger high odour events

“Bubbles of odour”

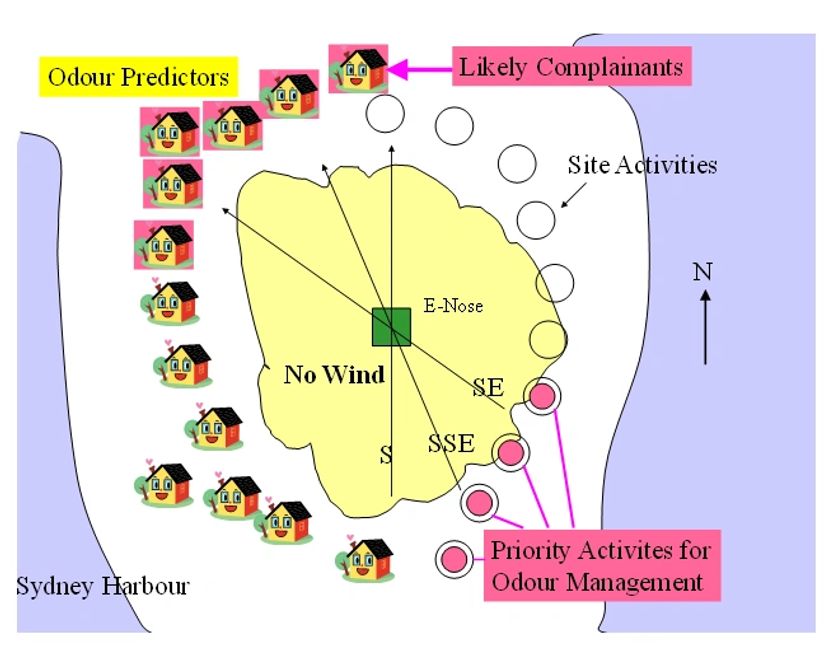

Odours consist of mixtures of airborne chemical species carried in the air from an emitting source of molecules. Air is fluid, and the smelly molecules (and others that are not smelly) flow away from the source akin to a liquid being poured into water. If there is nothing pushing the air (i.e. wind) the molecules disperse evenly away from the emission point. This can happen to the molecules making up a “smell” when the wind falls away and a perfect calm results. Sometimes this happens at night or when the wind changes direction, blowing in one direction, then stopping and blowing the opposite way. During these lulls, odour can build up in a three dimensional “bubble” above the odour source. This was observed during an E-Nose Pty Ltd study of a tank farm on the edge of Sydney harbour. In the calm of certain nights, odour build up and when the sea breeze picked up, the odour was smelled by the nearby residents:

Odour measured at the static monitoring point detected the build up overnight but the complaints arose only when the wind pushed the “bubble” and the contribution from tanks in the SE and SSE, over the houses in the NW, as shown in the figure, above. This led to predictive guidance for management in dealing with complainants in the community. Lighter molecules (less dense than air) will move to the top of the bubble. The makeup of the mixture reaching the complainants after this weather phenomenon may consist of a slightly different mix (because the lighter molecules will be higher off the ground) than when the wind blows steadily across the source and toward the human population. In general people know the smell and give it a description based on where they think the smell is coming from: e.g. “the lagoon” or “the tank farm”.

Wind

Wind is the main way that a stream of odour molecules reaches a community living at a distance from the source. If the emission is short-lived (as when a tank is vented) and the wind is weak, the odour will take time to move across the land and the area where people live, downwind of the emission. The stronger the wind, the quicker the wind will blow the odour molecules away. If the emission is long lasting, the wind strength will have an effect of shortening the exposure, but the on-going nature of the emission will mean that people will experience the smell as continuous and probably as more disturbing to them. Odours cannot be detected upwind from an odour source. E-Nose Pty Ltd have measured odour from the vent of a bitumen tank at millions of times higher than human threshold a few metres downwind from the vent, but zero the same distance upwind. Molecules in a moving fluid may form eddies and swirls of varying concentration, but they do not flow against the wind. Information on wind speed and direction is useful in understanding dispersion and impact of odours.

Heat, Cold and dynamic odour release

The ambient temperature determines the amount of smell released from a static source, because molecules are released from a material by heat. In cold weather smells become “locked in” to their static sources. If the source is dynamic, such as in an industrial manufacturing process, the active release of the molecules (such as up a chimney stack) will be the main driver of the odour into the air, whereupon the wind will move the stream in a particular direction. Plume modelling is a way of predicting how far the molecules will travel. Parameters in a plume model include height of point of release, the heat propelling it up the stack, the material being released (relative density to air), the wind direction, the topography of the terrain and obstacles (trees, buildings, downwind of the point of emission.

Copyright © 2020 E-Nose Pty Ltd - All Rights Reserved.